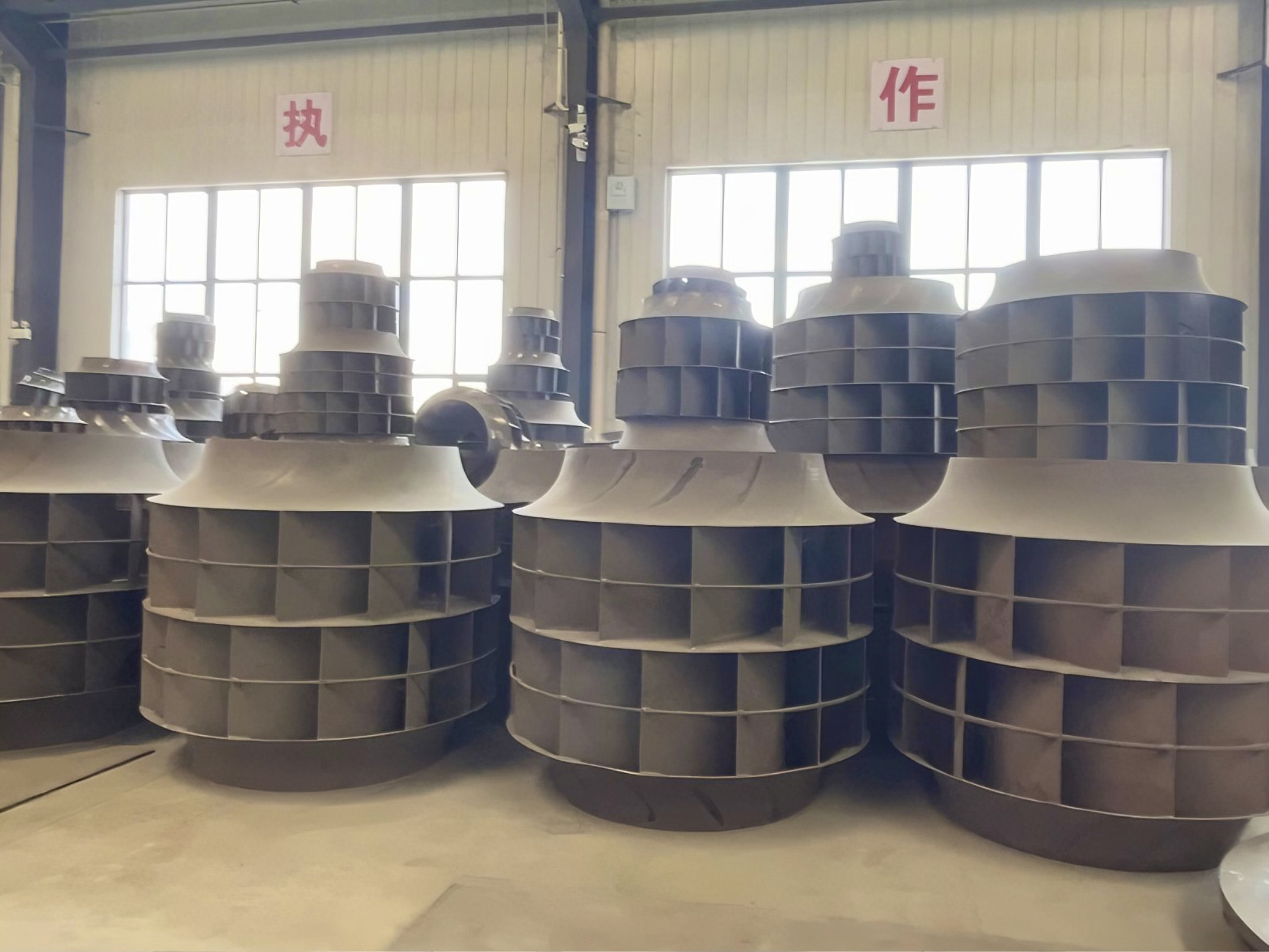

Wan kun fan science popularization - Fan Manufacturing Process of Impeller Annealing

The process of impeller annealing involves heating the impeller to the appropriate temperature, holding it at that temperature for a certain period of time, and then slowly cooling it down. In the processing of fan impellers, special forming fixtures are used to securely hold the workpiece, and the workpiece is then placed together with the fixtures in a vacuum annealing furnace. The furnace is heated to 450-470°C, held at that temperature for 2.5-3 hours, and then cooled in the furnace before being taken out and allowed to air cool to room temperature. This process not only eliminates residual stresses from welding but also corrects the deformation of the blades and discs, laying the foundation for ensuring the impeller's design performance.

Objective:

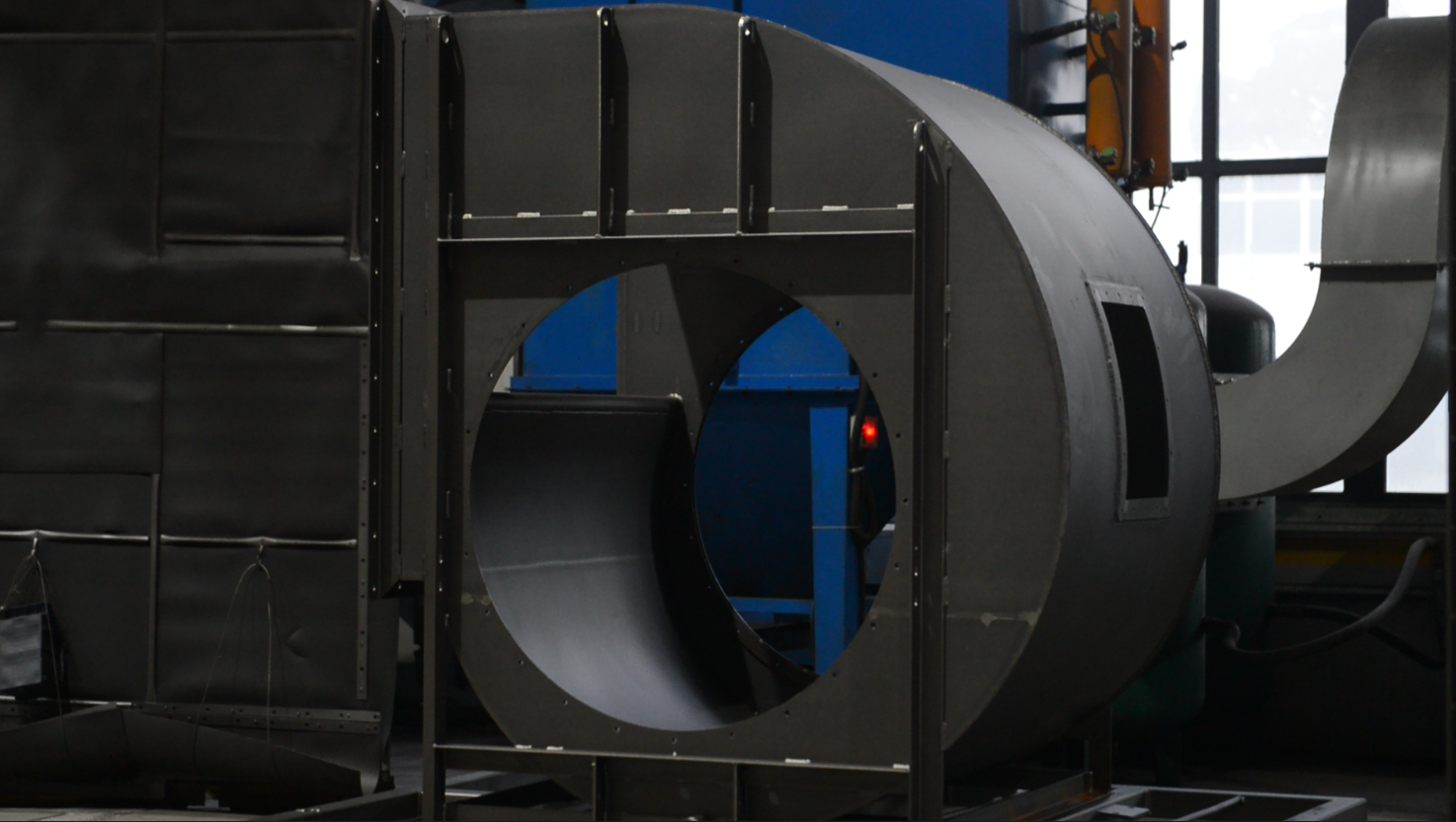

1. Reduce hardness and enhance malleability: This makes it easier to perform machining and cold deformation processes on the impeller material, such as cutting and bending, thereby reducing the difficulty of these processes and improving their efficiency and quality.

2. Uniform organization and refinement of crystal grains: For cast or forged impellers, annealing can make the internal organization more uniform and the crystal grains finer, thereby improving the impeller's mechanical properties, such as strength and toughness, and laying a solid foundation for subsequent use and further processing.

3. Eliminating internal stresses and work hardening: During the manufacturing process of impellers, such as casting, forging, and welding, internal stresses and work hardening may occur. Annealing can eliminate these internal stresses, prevent the impeller from deforming or cracking in subsequent use, and also eliminate work hardening, thereby restoring the material to a better state for processing.