Firstly, let me introduce what working conditions require the use of axial flow fans. Simply put, the working principle of axial flow fans is the same as that of general household fans. Ventilation fans that allow gas to flow along the axial direction are called axial flow fans. What are the main components of industrial axial flow fans and centrifugal fans? The difference between household fans and axial fans lies in the air pressure of the fan. Axial fans are generally used in situations where the air pressure is below 490Pa.

1、 Composition and structure of axial flow fan:

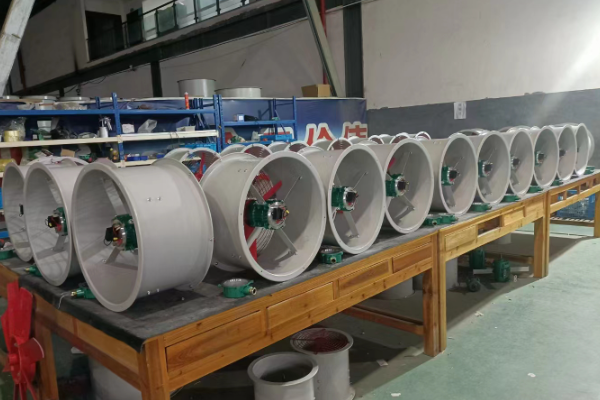

Axial flow fan is mainly composed of six parts: collector, impeller, front guide vane, rear guide vane, diffuser, and electric motor. I won't introduce the structure of the product one by one, after all, these components definitely have their functions and uses.

2、 Material of axial flow fan:

Different materials will definitely be used for different operating conditions, and the cost of the products produced will vary depending on the material. This problem can be easily explained. Carbon steel, stainless steel, fiberglass, aluminum alloy, high-strength steel, so different materials will result in different costs for axial flow fans. Today I will mainly explain the categories of carbon steel materials. The main components involved in the use of carbon steel materials for axial flow fans are the collector, impeller, front guide vane, rear guide vane, diffuser, and five major parts. These five parts can be divided into two types: integrated and split. The cost of integrated materials is low, but the processing complexity is high, and the cost is higher than that of split type processing; The cost of split type materials is high because it involves an increase in materials at the connection point, but the processing difficulty is weak, so the processing cost is lower than that of integrated type. Whether it is integrated type or split type, the overall cost will not differ too much because the assembly cost of split type is slightly higher than that of integrated type. So the basic structural cost difference is not significant. Another issue is the selection of carbon steel materials, including regular materials, secondary materials, cold plates, and hot plates. Different materials can have varying prices.

3、 Electric motors used according to operating conditions:

At present, the operating conditions of axial flow fans that I am familiar with are generally divided into: general ventilation, air exchange, and ordinary motors; Motors that can withstand high temperature conditions; Moisture resistant motors with wet working conditions; Explosion proof motors under flammable and explosive conditions. These are the four main types, and there may be other types as well, but I am inexperienced and only understand this type of working condition.