The 4-72 centrifugal fan can transport air and other unnatural, harmful to human health, and non corrosive gases to steel. Viscous substances are not allowed in the gas, and the dust and hard particles contained should not exceed 150MG/M3. The gas temperature should not exceed 80 ℃. This fan has good aerodynamic performance, balanced operation, low vibration, high efficiency, and long service life. Widely applicable for indoor ventilation and air exchange in industrial and mining enterprises, large buildings, hotels and restaurants.

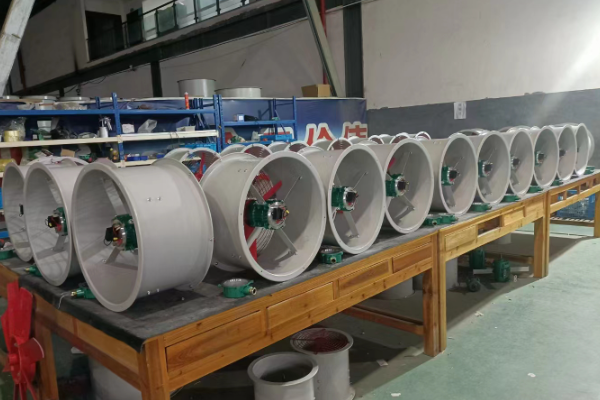

B/F4-72A series fiberglass centrifugal fan

Purpose:

The F4-72 fiberglass centrifugal fan is made of fiberglass composite material based on the performance parameters of the metal 4-72 fan. This series of fans can transport corrosive gases containing acidic, alkaline, and chemical components. The transported gas is not allowed to contain viscous substances, dust and hard particles ≤ 150mg/m3, gas temperature ≤ 70 ℃, and relative humidity ≤ 100% This series of fans has the characteristics of high strength, light weight, resistance to aging, good corrosion resistance, low noise, and smooth operation. It is an ideal universal anti-corrosion and acid alkali resistant fan. This series of fans is widely used in places containing corrosive gases such as chemical, electroplating, oxidation, power plants, laboratories, circuit boards, and environmental protection equipment.

Structural form and characteristics:

The F4-72A fan is mainly composed of an impeller, a casing, an electric motor, etc. The bracket is made of profiles and connected to the air duct.

(1) Impeller section: composed of blades and hub, both made of fiberglass.

(2) Shell section: composed of a shell and air vents, both made of fiberglass.

(3) The air inlet and casing are made of fiberglass as a whole, with a curved shape on the side of the fan and the axial plane, which allows gas to enter the impeller smoothly with minimal loss.

(4) Motor Department: Adopt anti-corrosion centrifugal fan specialized horizontal motor, and spray anti-corrosion paint on the surface of the body.

2. This series of fans has high aerodynamic efficiency, low noise, and strong corrosion resistance.

3. Applicable medium temperature range: -20 ℃ -70 ℃, medium relative humidity ≤ 100%, dust content ≤ 100mg/m3.

One Precautions for installation and use of industrial centrifugal fans

1. When installing the fan, it is necessary to first check whether the connections of each component are firm, whether the rotation is flexible, and whether there are any debris inside the casing.

2. When connecting the fan and foundation interface, as well as the inlet and outlet air ducts, they should be adjusted to fit naturally. Forced connections are not allowed, and the weight of the air ducts must not be concentrated on the casing to prevent deformation and affect normal operation. The inlet and outlet ducts of the fan should be connected with hoses, and attention should be paid to the horizontal position of the fan.

3. After installation, try to rotate the impeller and check if it is flexible. If any abnormalities are found, they should be adjusted in a timely manner.

4. The trial operation can only be carried out after the installation is completed and all parts are normal. During the trial operation, the current must be strictly controlled and cannot exceed the rated value. To prevent the motor from burning out due to overload, the fan must be started and tested under no-load conditions. If the situation is good, gradually open the valve until it reaches the specified working condition.

II Maintenance system for centrifugal fan

1. The fan must be used and maintained by a dedicated person.

2. Fans are not allowed to operate with defects.

3. Regularly remove dust inside the fan, especially impurities such as dust and dirt on the impeller, to prevent rust and imbalance.

4. Wind turbine maintenance must emphasize the importance of first shutting down the power supply and stopping the machine.

5. Normally, lubricating oil should be replaced every 3-6 months, except after each disassembly and repair.